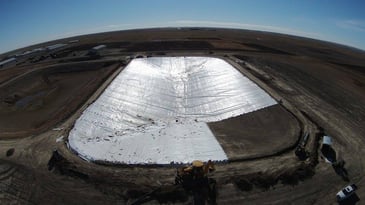

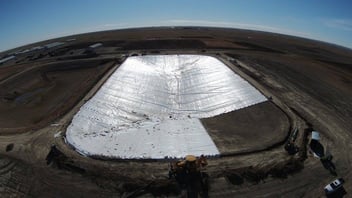

HDPE vs LLDPE Liners

When the time comes to select a geomembrane for a new containment project, the question often arises, which is best for a particular purpose. Well, it ultimately depends on what project you'll use it in, whether it's in agriculture, water management, construction, oil and gas, or as secondary containment. There are many options available, each with its advantages and disadvantages that make them suitable for a specific project.

Despite the variety of choice, HDPE and LLDPE are the most commonly suggested geomembranes in containment projects because both of them have excellent chemical resistance qualities.

There are, however, some differences between the two that you need to consider before making your choice. This post will outline the main differences between these to geomembranes to make your choice easier.

Molecular Structure

The main difference between the two is the way their molecules bond with each other and how tightly they are formed. This, to a large extent, influences the other engineering properties they have.

High-Density Polyethylene (HDPE) is free of both long and short branching. Because of this absence, it has high intramolecular forces and greater rigidity. This gives it excellent chemical resistance qualities and durability but can make it prone to stress cracking.

In contrast, Linear Low-Density Polyethylene (LLDPE) is distinguished by chain branching distributed evenly along the length of the chain. This makes LLDPE far more flexible than HDPE. Thus, unlike HDPE, it's less prone than stress cracking and makes it easier to handle.

Flexibility

Apart from the molecular structure dictating the rigidity of the product, crystalization because of

this molecular structure also plays a role.

LLDPE is considered a low crystalline polyethylene with a crystallinity in the range of 5%. Because of this, it's more flexible and easier to stretch, making it easier to adapt to its environment. Being flexible, it can also be prefabricated ahead of schedule and it won't be damaged by folding it over itself.

Compared to LLDPE, HDPE is a semi-crystalline polymer with a crystallinity of about 50%. This makes it more rigid and less adaptable to its environment. Unlike LLDPE, it can't be prefabricated and has to be welded on-site, and its lack of flexibility can lead to damage when it's folded over itself.

Weather and UV Resistance

While LLDPE is resistant to weathering and UV damage, HDPE comes out on top in this respect. It can hold up to the daily battering from the sun and the elements. LLDPE's life span can, however, be extended by adding additional additives during the manufacturing process.

Permeability

Its dense cell structure makes HDPE less permeable than LLDPE. In other words, on a molecular level, it's less likely for molecules to pass through it. For applications where you need a containment liner as a strong chemical barrier, like landfill base liners, HDPE is indispensable.

Conclusion

The hope is that with this short introductory guide, you'll be able to choose a geomembrane from your next containment project. But remember, ultimately, it comes down to preference and the project requirements that will dictate which containment liner should be used.

Did you find this short post helpful? Do you need any more information on containment liners and geomembranes? Feel free to contact us with any of your questions, we'd love to hear from you.

Leave a Comment